THE FUTURE OF 3D PRINTING: TRENDS TO WATCH IN ADDITIVE MANUFACTURING

The world of 3D printing has come a long way since its inception, and it’s only getting better. With the rise of additive manufacturing, the future of 3D printing is looking brighter than ever. From aerospace to healthcare, 3D printing is revolutionizing the way we design and manufacture products. In this blog post, we’ll explore the latest trends in additive manufacturing and what they mean for the future of 3D printing. We’ll delve into the latest advancements in materials, software, and hardware, and how they’re changing the game for product design and invention.

So, whether you’re an entrepreneur looking to bring your invention idea to life or a product designer looking to stay ahead of the curve, this post is for you. Let’s dive in and explore the exciting world of additive manufacturing!

THE FUTURE OF 3D PRINTING: TRENDS TO WATCH IN ADDITIVE MANUFACTURING

The world of 3D printing has come a long way since its inception in the 1980s. From being a niche technology used primarily for prototyping, it has now become a mainstream manufacturing process used in a wide range of industries. The future of 3D printing looks bright, with new trends emerging that promise to revolutionize the way we design and manufacture products. In this article, we will explore some of the key trends to watch in additive manufacturing.

-

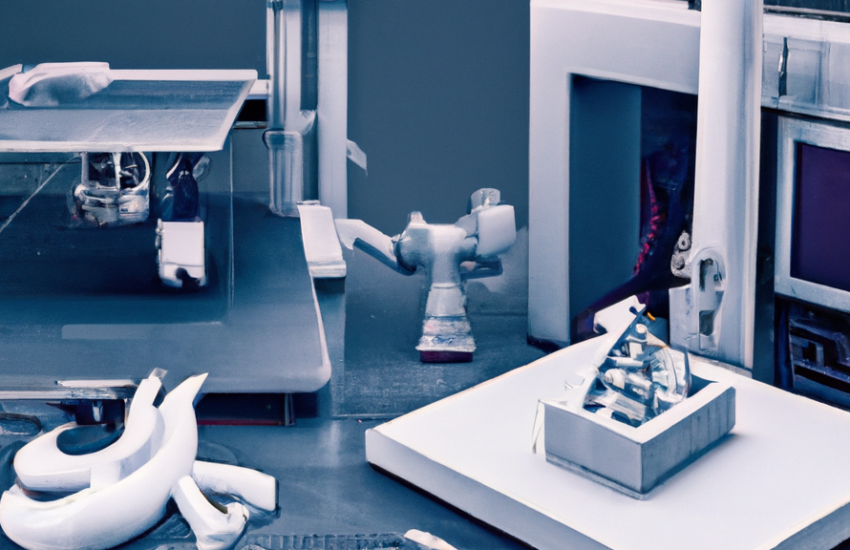

Increased Adoption of Metal 3D Printing

One of the most significant trends in 3D printing is the increased adoption of metal 3D printing. While plastic 3D printing has been around for a while, metal 3D printing is a relatively new technology that is gaining traction. Metal 3D printing allows for the creation of complex geometries that are difficult or impossible to achieve with traditional manufacturing methods. It also enables the production of parts with superior mechanical properties, making it ideal for use in industries such as aerospace, automotive, and medical.

-

Advancements in Materials

Another trend to watch in additive manufacturing is the advancements in materials. As 3D printing technology continues to evolve, so do the materials used in the process. New materials are being developed that offer improved properties such as strength, durability, and flexibility. For example, carbon fiber reinforced polymers are being used to create parts that are stronger and lighter than traditional materials. This trend is expected to continue, with new materials being developed that will enable the creation of even more complex and functional parts.

-

Integration with Other Technologies

3D printing is not an isolated technology, and it is increasingly being integrated with other technologies to create more advanced manufacturing processes. For example, 3D printing can be combined with robotics to create automated manufacturing systems that can produce parts around the clock. It can also be integrated with artificial intelligence to optimize the design and production process. This trend is expected to continue, with 3D printing being integrated with other technologies such as blockchain, IoT, and augmented reality.

-

Increased Accessibility

As 3D printing technology becomes more advanced, it is also becoming more accessible. The cost of 3D printers has decreased significantly over the years, making it more affordable for small businesses and individuals to invest in the technology. Additionally, 3D printing services are becoming more widely available, allowing anyone to have their designs printed without the need for a 3D printer. This trend is expected to continue, with 3D printing becoming even more accessible in the future.

-

Customization and Personalization

One of the most significant advantages of 3D printing is the ability to create customized and personalized products. With 3D printing, it is possible to create unique products that are tailored to the specific needs of the customer. This trend is expected to continue, with 3D printing being used to create everything from personalized medical implants to customized fashion accessories.

-

Sustainability

Sustainability is becoming an increasingly important consideration in manufacturing, and 3D printing is no exception. 3D printing has the potential to be a more sustainable manufacturing process than traditional methods, as it produces less waste and uses fewer resources. Additionally, 3D printing can be used to create products that are designed for disassembly and recycling, further reducing the environmental impact. This trend is expected to continue, with 3D printing being used to create more sustainable products and manufacturing processes.

-

Bioprinting

Bioprinting is a relatively new application of 3D printing that involves the creation of living tissue and organs. While still in the early stages of development, bioprinting has the potential to revolutionize the medical industry by enabling the creation of replacement organs and tissues. This trend is expected to continue, with bioprinting being used to create more complex and functional tissues and organs.

Conclusion

The future of 3D printing looks bright, with new trends emerging that promise to revolutionize the way we design and manufacture products. From increased adoption of metal 3D printing to advancements in materials and integration with other technologies, 3D printing is poised to become an even more powerful tool for innovation and invention. As the technology continues to evolve, we can expect to see even more exciting developments in the world of additive manufacturing.

- The future of 3D printing – additive manufacturing experts forecast …

Jan 25, 2022 … If you want a near-term view of the current 3D printing trends to watch then read our previous article. Which 3D printing materials are expected … - The Future of 3D Printing: Five Predictions | Jabil

But as additive manufacturing technology adoption grows, … It doesn’t take a crystal ball to see that the future of 3D printing is bright. - What is the future of 3D printing? 80 additive manufacturing experts …

Jan 25, 2023 … A key trend to watch will be how the 3D printing industry uses AI. ChatGPT and generative image software such as Midjourney and DALL-E have … - 6 Predictions for the Future of 3D Printing

Aug 23, 2022 … Six predictions about the near future of additive manufacturing. … 3D printing is quickly becoming a mature manufacturing technology. - 10 Predictions on the Future of 3D Printing [Expert Roundup] – AMFG

Aug 21, 2019 … 1. 3D printing will become a mainstream technology for serial production; 2. Design software for additive will become more integrated and … - 3D Printing Trends to Watch in 2018 | Cad Crowd

Oct 10, 2018 … As 2017 draws to a close, we’re optimistic about the future of 3D printing in the coming year. Investment in the additive manufacturing sector, … - 5 Trends Shaping The Future of Additive Manufacturing [2021] – AMFG

Feb 18, 2021 … What does 2021 have in store for the 3D printing industry? Here are our five key trends shaping the future of additive manufacturing… - What Does the Future of 3D Printing Look Like? – Fusion 360 Blog

Jan 5, 2021 … As technology continues to evolve, the future is brighter than ever. woman-3d-printing-additive manufacturing. Once a novelty pipe dream but now … - Predicting the future of additive manufacturing: A Delphi study on …

Additive manufacturing (colloquially: 3D printing) is a highly discussed topic. Previous research has argued that this technology not only has profound … - What’s the Future of 3D Printing?

Apr 5, 2022 … Engineers with 3D printer in foreground … The proprietary technology gives Xometry deep insight into additive manufacturing trends.

The lesser-known side of The Future of 3D Printing: Trends to Watch in Additive Manufacturing

- The first 3D printer was invented in the mid-1980s by Chuck Hull, who founded 3D Systems Corporation.

- Additive manufacturing, or 3D printing, has been used for prototyping and small-scale production since its inception but is now being increasingly adopted for large-scale manufacturing.

- In recent years, advancements in materials science have allowed for the creation of stronger and more durable parts using additive manufacturing techniques.

- One of the most promising applications of additive manufacturing is in healthcare where it can be used to create custom prosthetics and implants that are tailored to individual patients’ needs.

- NASA has been exploring the use of additive manufacturing on space missions as a way to reduce costs and increase efficiency by allowing astronauts to print tools and replacement parts on demand rather than having to bring everything with them from Earth.

- The automotive industry has also embraced additive manufacturing as a way to produce lighter weight components that improve fuel efficiency without sacrificing strength or durability.

- Additive Manufacturing is not limited only up-to plastic products; it can also be used with metals like titanium which makes it useful even in aerospace industries

Are you ready to become an inventor?

Getting your idea out of your head and into your hands is only the first in a long set of steps towards becoming a successful inventor.

First Steps To A Successful Invention

At Invention Therapy, we believe that the power of the internet makes it easier than you think to turn your invention idea into a reality. In most cases, you can build a prototype and start manufacturing a product on your own. Changing your way of thinking can be difficult. Being an inventor requires you to balance your passion with the reality of having to sell your products for a profit. After all, if we can't make a profit, we won't be able to keep the lights on and continue to invent more amazing things!Please subscribe to our Youtube Channel!