THE FUTURE OF INVENTION DESIGN: HOW CNC MACHINING IS ENHANCING PRECISION AND QUALITY

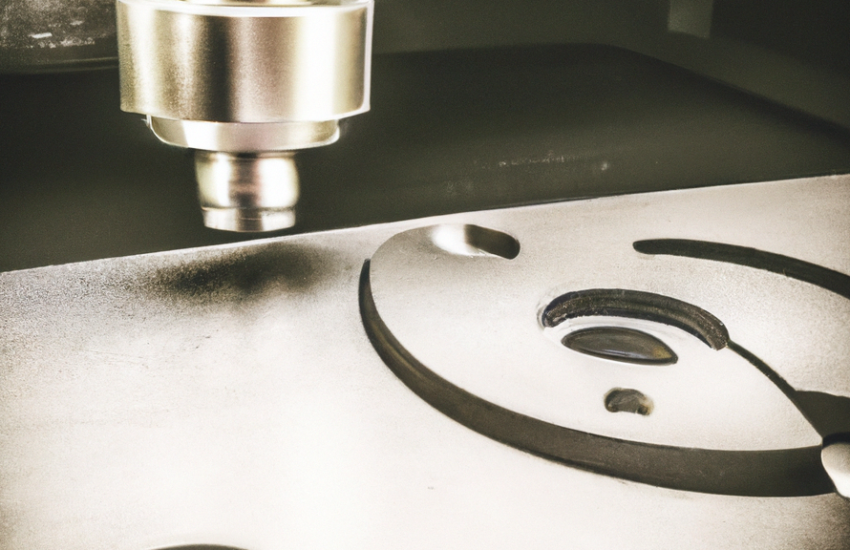

Invention design has come a long way since the days of hand-drawn sketches and clay models. Today, with the help of computer-aided design (CAD) software and computer numerical control (CNC) machining, inventors can create precise and high-quality prototypes in a fraction of the time it used to take. CNC machining, in particular, has revolutionized the way inventors approach product design. By using computer-controlled machines to cut and shape materials, inventors can achieve levels of precision and accuracy that were once impossible.

In this blog post, we’ll explore the future of invention design and how CNC machining is enhancing precision and quality. From the benefits of using CNC machines to the latest advancements in the field, we’ll cover everything you need to know to stay ahead of the curve. So, whether you’re an inventor looking to bring your ideas to life or simply interested in the latest trends in product design, read on to discover how CNC machining is shaping the future of invention.

THE FUTURE OF INVENTION DESIGN: HOW CNC MACHINING IS ENHANCING PRECISION AND QUALITY

In today’s fast-paced world, innovation is the key to success. The ability to create new products and designs that meet the needs of consumers is essential for businesses to stay competitive. However, the process of invention design can be challenging, especially when it comes to precision and quality. This is where CNC machining comes in.

CNC machining is a manufacturing process that uses computer-controlled machines to create precise and complex parts. It has revolutionized the way products are designed and manufactured, making it easier to produce high-quality products with greater accuracy and efficiency.

The Benefits of CNC Machining

CNC machining offers several benefits that make it an ideal choice for invention design. One of the most significant advantages is precision. CNC machines can produce parts with incredible accuracy, down to the micrometer level. This level of precision is essential for creating complex designs that require tight tolerances.

Another benefit of CNC machining is speed. Traditional manufacturing methods can be time-consuming and labor-intensive, but CNC machines can produce parts quickly and efficiently. This means that businesses can bring their products to market faster, giving them a competitive edge.

CNC machining also offers greater flexibility in design. With traditional manufacturing methods, creating complex designs can be challenging, if not impossible. CNC machines, on the other hand, can create intricate shapes and designs with ease. This means that businesses can create products that are not only functional but also aesthetically pleasing.

The Future of Invention Design

The future of invention design is exciting, with new technologies and innovations emerging all the time.

One of the most significant trends in invention design is the use of 3D printing. 3D printing allows businesses to create prototypes quickly and easily, making it easier to test and refine their designs.

However, while 3D printing is an excellent tool for prototyping, it has its limitations when it comes to production. This is where CNC machining comes in. CNC machines can produce parts with greater accuracy and speed than 3D printers, making it an ideal choice for mass production.

Another trend in invention design is the use of artificial intelligence (AI). AI can help businesses analyze data and identify patterns, making it easier to create products that meet the needs of consumers. AI can also help with the design process, suggesting improvements and optimizations that humans may not have considered.

CNC Machining and AI

The combination of CNC machining and AI is a powerful one, offering businesses even greater precision and efficiency in invention design. AI can help optimize the design process, identifying areas where CNC machining can be used to create parts with greater accuracy and speed.

For example, AI can analyze a design and identify areas where traditional manufacturing methods may not be suitable. It can then suggest using CNC machining to create those parts, ensuring greater precision and quality.

AI can also help with quality control. CNC machines can produce parts with incredible accuracy, but there is always the risk of errors. AI can analyze the parts as they are produced, identifying any defects or inconsistencies. This means that businesses can catch and correct issues before they become a problem.

The Future of Invention Design: Conclusion

In conclusion, the future of invention design is bright, with new technologies and innovations emerging all the time. CNC machining is one of the most significant advancements in manufacturing, offering businesses greater precision, speed, and flexibility in product design.

The combination of CNC machining and AI is even more powerful, offering businesses even greater precision and efficiency in invention design. With AI’s ability to analyze data and identify patterns, and CNC machining’s ability to produce parts with incredible accuracy, businesses can create products that meet the needs of consumers with greater ease.

As the world becomes more competitive, businesses must stay ahead of the curve when it comes to invention design. By embracing new technologies like CNC machining and AI, businesses can create products that are not only functional but also aesthetically pleasing, giving them a competitive edge in the marketplace.

- 5 Critical Prototyping Services To Pay Attention To During Product …

Apr 29, 2020 … It’s also done through subtractive methods like CNC Machining … with new designs to enhance precision by inventors and customers. - Precision CNC Machining – Metal Cutting Corporation

Oct 19, 2020 … Taking a computer aided design (CAD) model provided by a customer, an expert machinist uses computer aided manufacturing software (CAM) to … - CNC History: The Origination and Evolution of CNC Machining 0

Jan 12, 2021 … CNC machining has developed over a long time. … come from low-quality and low-precision manufacturing process. … Who Invented CNC? - Screw Machining Shop

Anco Precision is dedicated to the quality manufacturing of precision screw machine products, with your design and specifications at the best price and … - Machine learning and artificial intelligence in CNC machine tools, A …

Jan 14, 2023 … Moreover, surface quality of machined components can be predicted and … [24], [25], [26], [27] provided improvement of CNC machining in … - CNC Machining for the Medical Industry – WH Bagshaw

Swiss-style CNC machines were invented for the purpose of creating the … to our commitment to quality, customer service and continuous improvement. - Substantial capabilities of robotics in enhancing industry 4.0 …

Robotics is progressively leading to the manufacturing of quality products while … Robots are precision designed such that the output and services can be … - CNC Machining – Tight Tolerances and Superior Quality

Precision Metal Components are a quality focused provider of custom CNC machined parts. We specialize in CNC Turning and CNC milling. - Improving Surface Roughness of CNC Milling Machined Aluminum …

The objective of this research was to study the effects of CNC machining … the world use CNC machine to produce high quality precise parts for different … - Blog | Custom Manufacturing FL

Enhance Your CNC Machined Parts with In-House Laser Engraving Services … Avoid common precision machining challenges by carefully designing your part, …

The lesser-known side of The Future of Invention Design: How CNC Machining is Enhancing Precision and Quality

- The first patent law was established in Venice, Italy in 1474.

- Thomas Edison held over 1,000 patents for his inventions including the light bulb and phonograph.

- The concept of a “patent troll” refers to individuals or companies who acquire patents solely for the purpose of suing others for infringement.

- Invention design often involves multiple iterations and prototypes before a final product is produced.

- Intellectual property rights protect inventors from having their ideas stolen or copied without permission.

- Many famous inventions were created by accident such as penicillin and Post-it notes.

- The process of obtaining a patent can take several years and cost thousands of dollars in legal fees alone.

- Rapid prototyping technologies like 3D printing have revolutionized invention design by allowing faster production times at lower costs than traditional methods like CNC machining

Are you ready to become an inventor?

Getting your idea out of your head and into your hands is only the first in a long set of steps towards becoming a successful inventor.

First Steps To A Successful Invention

At Invention Therapy, we believe that the power of the internet makes it easier than you think to turn your invention idea into a reality. In most cases, you can build a prototype and start manufacturing a product on your own. Changing your way of thinking can be difficult. Being an inventor requires you to balance your passion with the reality of having to sell your products for a profit. After all, if we can't make a profit, we won't be able to keep the lights on and continue to invent more amazing things!Please subscribe to our Youtube Channel!