THE BENEFITS OF CNC MACHINING: HOW TO USE COMPUTER-AIDED MANUFACTURING TO CREATE PARTS

In today’s fast-paced world, the manufacturing industry is constantly evolving, and the use of computer-aided manufacturing (CAM) has become increasingly popular. One of the most significant advancements in CAM is CNC machining, which has revolutionized the way parts are created. CNC machining is a process that uses computer-controlled machines to create precise and complex parts with ease. This technology has numerous benefits, including increased accuracy, faster production times, and reduced labor costs. In this article, we will explore the benefits of CNC machining and how it can be used to create parts for your invention or product design.

Whether you are a seasoned inventor or just starting, understanding the advantages of CNC machining can help you create high-quality parts that meet your specific needs. So, let’s dive in and discover the world of CNC machining!

In today’s world, technology has revolutionized the way we live, work, and create.

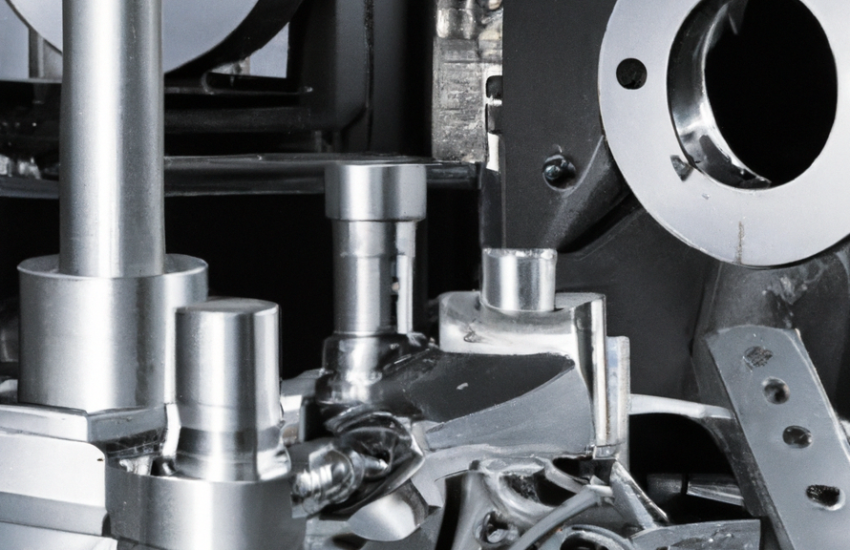

One of the most significant advancements in manufacturing is the use of Computer Numerical Control (CNC) machining. CNC machining is a manufacturing process that uses computer software to control the movement of machines and tools to create parts. This technology has numerous benefits that make it an essential tool for inventors, designers, and manufacturers.

Benefits of CNC Machining

- Precision: CNC machines can produce parts with incredible accuracy, often within a few thousandths of an inch. This level of precision is impossible to achieve with traditional manufacturing methods, such as manual milling or turning. CNC machines can also produce complex shapes and designs that would be difficult or impossible to create with traditional methods.

- Speed: Once a design is programmed into the machine, it can produce parts quickly and efficiently. This speed is especially useful for large production runs, where traditional methods would be too slow and costly. CNC machines can also operate 24/7, allowing for continuous production without the need for human intervention.

- Consistency: CNC machines produce parts with the same level of precision and consistency every time. This consistency is essential for industries such as aerospace and medical, where even the slightest variation can have significant consequences.

- Versatility: CNC machines can work with a wide range of materials, including metals, plastics, and composites. They can also produce parts in a variety of sizes, from small components to large structures. This versatility makes CNC machining an ideal tool for inventors and designers who need to create prototypes or small production runs.

- Automation: Once a design is programmed into the machine, it can operate without the need for human intervention. This automation reduces the risk of errors and increases efficiency. It also frees up human operators to focus on other tasks, such as quality control and maintenance.

- Cost-effectiveness: While the initial investment in a CNC machine can be significant, the long-term cost savings are substantial. CNC machines can produce parts quickly and efficiently, reducing labor costs. They also produce less waste than traditional methods, reducing material costs. Additionally, CNC machines require less maintenance than traditional machines, reducing maintenance costs.

- Customization: CNC machines can produce custom parts quickly and efficiently. This customization is essential for industries such as automotive and aerospace, where each part must be tailored to specific requirements.

- Environmental advantages: CNC machines produce less waste than traditional methods, reducing the environmental impact of manufacturing. They also use less energy, reducing carbon emissions and energy costs.

Applications of CNC Machining

So, how can inventors, designers, and manufacturers use CNC machining to create parts? The first step is to create a design using Computer-Aided Design (CAD) software. This software allows designers to create 3D models of their parts, which can then be programmed into the CNC machine. Once the design is programmed, the CNC machine will use its cutting tools to create the part.

It is essential to choose the right CNC machine for the job. There are many different types of CNC machines, each with its own strengths and weaknesses. For example, a CNC lathe is ideal for creating cylindrical parts, while a CNC mill is better suited for creating complex shapes and designs.

It is also important to choose the right material for the part. CNC machines can work with a wide range of materials, but each material has its own properties and characteristics. For example, metals are strong and durable, but they can be difficult to machine. Plastics are lightweight and easy to machine, but they may not be as strong as metals.

Once the part is created, it is essential to perform quality control checks to ensure that it meets the required specifications. This can be done using a variety of methods, such as visual inspection, measurement, and testing.

Conclusion

In conclusion, CNC machining is a powerful tool for inventors, designers, and manufacturers. Its precision, speed, consistency, versatility, automation, cost-effectiveness, customization, and environmental advantages make it an essential tool for modern manufacturing. By using CAD software and choosing the right CNC machine and material, inventors and designers can create parts quickly and efficiently, while maintaining a high level of quality control.

- What is CAM (Computer-Aided Manufacturing)? – Fusion 360 Blog

Mar 17, 2021 … For example, a CNC router used for woodworking can make easy work of cutting plywood into cabinet parts. It can also easily tackle complex … - What is CNC Machining? | Goodwin College

Jun 27, 2018 … The parts’ mechanical dimensions are defined using computer-aided design (CAD) software, and then translated into manufacturing directives by … - CAM software for CNC Machining | Autodesk Fusion 360

Computer-aided manufacturing (CAM) software helps people create programs for various … This process often uses mills, lathes, or more complex machines. - Computer-aided manufacturing – Wikipedia

CAM is used in many schools alongside computer-aided design (CAD) to create objects. CAD model and CNC machined part … - What Is CAM (Computer Aided Manufacturing)?

Jun 27, 2018 … Computer Aided Manufacturing, or CAM, is another important part of this … numerical control (CNC) machine tools for manufacturing parts. - Computer-Aided Manufacturing (CAM) | Siemens Software

The definition of Computer-Aided Manufacturing, and how CAM software is used in … computer numerical control (CNC) machine tools for manufacturing parts. - What is CNC Machining? | Definition, Processes, Components & More

CAM: Computer-aided manufacturing (CAM) software are programs used extract the technical information from the CAD model and generate machine program necessary … - What is computer numerical control (CNC)? – TechTarget Definition

CNC is commonly used in manufacturing for machining metal and plastic parts. … engineers create a computer-aided design (CAD) drawing of the part to be … - CNC vs 3D Printing: What is the Difference? | AMI

Jun 8, 2022 … CNC machining can produce parts that are strong and have precise … into instructions using a computer-aided manufacturing (CAM) program. - https://www.fldoe.org/core/fileparse.php/18703/url…

Set up and operate a computerized-numerical-control (CNC) machine for lathe … Demonstrate basic computer-aided design/computer-aided manufacturing …

Interesting facts about The Benefits of CNC Machining: How to Use Computer-Aided Manufacturing to Create Parts

- CNC machining was first developed in the 1940s and 1950s as a way to automate the production of aircraft parts.

- The first CNC machines were controlled by punched tape, which was later replaced by computer software.

- One of the main benefits of CNC machining is its ability to produce highly precise and complex parts that would be difficult or impossible to make using traditional methods.

- Another advantage is that it can reduce waste and increase efficiency, since it allows for more accurate material usage and faster production times.

- Some common materials used in CNC machining include metals like aluminum, steel, brass, copper, titanium; plastics like ABS (Acrylonitrile Butadiene Styrene), polycarbonate (PC), polypropylene (PP); wood; foam; composites etc

- There are different types of CNC machines available such as milling machines , lathes , routers etc each with their own unique capabilities.

Are you ready to become an inventor?

Getting your idea out of your head and into your hands is only the first in a long set of steps towards becoming a successful inventor.

First Steps To A Successful Invention

At Invention Therapy, we believe that the power of the internet makes it easier than you think to turn your invention idea into a reality. In most cases, you can build a prototype and start manufacturing a product on your own. Changing your way of thinking can be difficult. Being an inventor requires you to balance your passion with the reality of having to sell your products for a profit. After all, if we can't make a profit, we won't be able to keep the lights on and continue to invent more amazing things!Please subscribe to our Youtube Channel!