THE ART OF LATHE MACHINING: TECHNIQUES FOR DEVELOPING PRECISION PARTS

Lathe machining is an essential process in the world of invention, product design, and manufacturing. It involves the use of a lathe machine to shape and cut materials into precise and intricate parts. The art of lathe machining requires a high level of skill and expertise to develop precision parts that meet the required specifications. Whether you are a seasoned machinist or a beginner, mastering the techniques of lathe machining is crucial to producing high-quality parts that meet the demands of your invention or product design.

In this article, we will explore the art of lathe machining and provide you with techniques that will help you develop precision parts with ease. So, let’s dive in and discover the secrets of lathe machining!

Lathe Machining: An Age-Old Technique for Precision Parts

Lathe machining is an age-old technique that has been used for centuries to create precision parts. It is a process that involves the use of a lathe machine to cut, shape, and form a piece of material into a desired shape or size. The art of lathe machining requires a high level of skill and precision, and it is a technique that is still widely used today in various industries, including manufacturing, engineering, and construction.

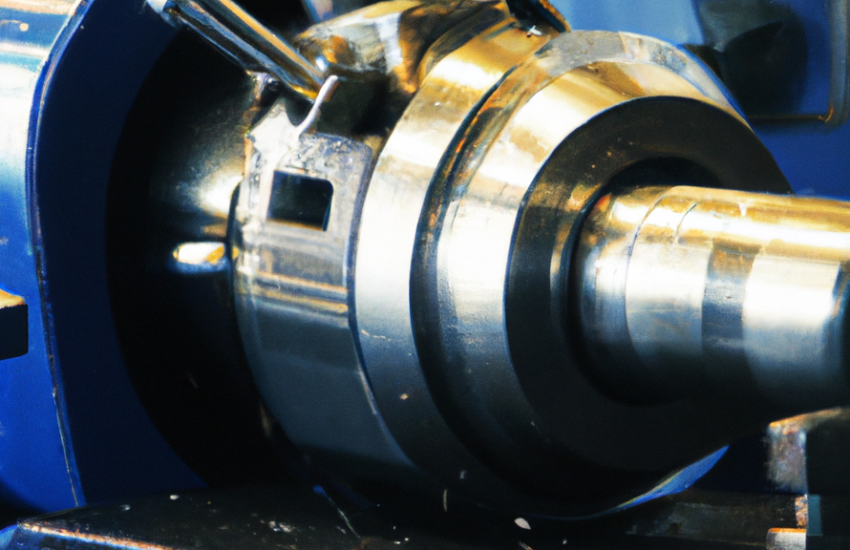

The lathe machine is a versatile tool that can be used to create a wide range of parts, from simple cylindrical shapes to complex geometries. The machine works by rotating a piece of material, such as metal or wood, while a cutting tool is used to remove material from the surface of the material. The cutting tool can be moved along different axes to create different shapes and sizes.

One of the key benefits of lathe machining is its ability to create precision parts. The lathe machine can be used to create parts with very tight tolerances, which means that the parts are very accurate and consistent in their dimensions. This is important in many industries where precision is critical, such as aerospace, automotive, and medical device manufacturing.

Techniques for Developing Precision Parts Using Lathe Machining

There are several techniques that can be used to develop precision parts using lathe machining. These techniques include:

- Centering: Centering is the process of aligning the material to the center of the lathe machine. This is important because it ensures that the material is rotating evenly and that the cutting tool is removing material evenly from all sides. Centering can be done using a variety of tools, including a center punch, a center drill, or a live center.

- Facing: Facing is the process of creating a flat surface on the end of a piece of material. This is typically done at the beginning of the machining process to ensure that the material is flat and even before any other cuts are made. Facing can be done using a facing tool, which is a cutting tool that is designed to create a flat surface.

- Turning: Turning is the process of removing material from the surface of the material to create a cylindrical shape. This is one of the most common techniques used in lathe machining and can be done using a variety of cutting tools, including a roughing tool, a finishing tool, and a parting tool.

- Drilling: Drilling is the process of creating a hole in a piece of material. This can be done using a drill bit that is mounted in the lathe machine. The drill bit can be moved along different axes to create holes of different sizes and shapes.

- Knurling: Knurling is the process of creating a pattern of small ridges on the surface of a piece of material. This is typically done to improve the grip of the material or to create a decorative pattern. Knurling can be done using a knurling tool, which is a cutting tool that is designed to create the ridges.

- Threading: Threading is the process of creating a screw thread on the surface of a piece of material. This is typically done using a threading tool, which is a cutting tool that is designed to create the thread. Threading can be done using a variety of thread types, including metric, imperial, and acme.

- Boring: Boring is the process of enlarging an existing hole in a piece of material. This can be done using a boring tool, which is a cutting tool that is designed to create a larger hole. Boring can be done to create a precise diameter or to create a tapered hole.

- Parting: Parting is the process of cutting a piece of material into two separate pieces. This can be done using a parting tool, which is a cutting tool that is designed to create a clean cut. Parting is typically done at the end of the machining process to separate the finished part from the remaining material.

Factors Affecting Precision in Lathe Machining

In addition to these techniques, there are several factors that can affect the precision of the parts created using lathe machining. These factors include:

- Material selection: The material used for lathe machining can have a significant impact on the precision of the parts created. Different materials have different properties, such as hardness, ductility, and thermal conductivity, which can affect how they respond to the cutting tool. It is important to select the right material for the job to ensure that the parts are precise and accurate.

- Cutting tool selection: The cutting tool used for lathe machining can also have a significant impact on the precision of the parts created. Different cutting tools have different geometries, coatings, and materials, which can affect how they cut the material. It is important to select the right cutting tool for the job to ensure that the parts are precise and accurate.

- Cutting parameters: The cutting parameters used for lathe machining, such as cutting speed, feed rate, and depth of cut, can also affect the precision of the parts created. It is important to optimize these parameters for the material and cutting tool being used to ensure that the parts are precise and accurate.

- Machine condition: The condition of the lathe machine itself can also affect the precision of the parts created. Wear and tear on the machine can cause it to become less precise over time, which can affect the accuracy of the parts created. It is important to maintain the machine properly to ensure that it is operating at peak performance.

Conclusion

In conclusion, the art of lathe machining is a technique that has been used for centuries to create precision parts. It is a versatile process that can be used to create a wide range of parts, from simple cylindrical shapes to complex geometries. The key to developing precision parts using lathe machining is to use the right techniques, select the right materials and cutting tools, optimize the cutting parameters, and maintain the machine properly. With these factors in mind, lathe machining can be a powerful tool for inventors, designers, and engineers looking to create precise and accurate parts for their products.

- CNC Precision Machining: A Detailed Guide to Know Its Process …

Aug 9, 2022 … If you’re looking to get custom precision machined parts, read this article … CNC precision machining refers to the process of creating … - Research and Development | About Us | Methods Machine Tools

Our team of engineering experts drive ongoing innovation with a passion for researching, analyzing, developing, testing, and validating the latest precision … - Metalworking – Wikipedia

Prior to the development of modern machining equipment it provided a relatively accurate means for the production of small parts, especially those with flat … - CNC Precision Machining Technology | Community College of …

Shaping the way Manufacturers OperateCNC Precision Machining Technology, … such as lathes, milling machines, and spindles to produce machined parts. - What is Machining? Intro To Machine Shop Processes & Tools

Jun 28, 2022 … Machine shops utilize equipment and tools like mills, lathes, … material on a workpiece in order to create a precise object or part. - Complex, Short & Medium Production Run Assembly Services

Mac Machine is adept in the assembly process. … machining for the development and production of highly sophisticated precision parts and assemblies. - Machining – Precision Products Inc – Machine Parts in Dalton, GA

We offer multiple Hyundai CNC lathes and Mazak CNC lathe with live tooling to produce the highest quality parts from our ISO9001:2008 certified process. Machine … - What Is A Machinist & What Do Machinists Do? The Crucible

Jun 28, 2022 … Machinists use machining tools to produce precise parts. They operate equipment such as mills, lathes, drills, and grinders to manufacture … - Precision Lathe Machining | Intrex Aerospace

The result is a process that is streamlined and efficient. Thin-Walled Machining. Many components that go into aerospace parts are designed not only for … - Trace-A-Matic: World-Class Precision Machining Quality Parts

Your source for precision machining of complex and intricate metal components that meets or exceeds the most critical tolerances.

The lesser-known side of The Art of Lathe Machining: Techniques for Developing Precision Parts

- The lathe machine was invented in ancient Egypt around 1300 BC.

- Leonardo da Vinci designed a lathe machine in the 15th century that could cut screws and threads.

- The Industrial Revolution saw the development of more advanced lathes, including automatic lathes that could produce identical parts quickly and efficiently.

- Lathes are used to create a wide range of products, from simple wooden bowls to complex aerospace components.

- CNC (computer numerical control) technology has revolutionized lathe machining by allowing for precise programming and automation of the process.

- Lathe machinists must have a strong understanding of materials science, as different metals require different cutting speeds and techniques for optimal results.

- Safety is paramount when operating a lathe machine, as high-speed spinning parts can be dangerous if not handled properly or with protective gear such as goggles or gloves

Are you ready to become an inventor?

Getting your idea out of your head and into your hands is only the first in a long set of steps towards becoming a successful inventor.

First Steps To A Successful Invention

At Invention Therapy, we believe that the power of the internet makes it easier than you think to turn your invention idea into a reality. In most cases, you can build a prototype and start manufacturing a product on your own. Changing your way of thinking can be difficult. Being an inventor requires you to balance your passion with the reality of having to sell your products for a profit. After all, if we can't make a profit, we won't be able to keep the lights on and continue to invent more amazing things!Please subscribe to our Youtube Channel!