THE ART OF LATHE MACHINING: TECHNIQUES FOR DEVELOPING COMPLEX PARTS

Lathe machining is an essential process in the manufacturing industry, and it has been around for centuries. The art of lathe machining involves the use of a lathe machine to shape and cut materials into complex parts. This technique is widely used in the production of various products, including automotive parts, aerospace components, and medical devices. Developing complex parts using lathe machining requires a high level of skill and expertise, and it is considered an art form by many professionals in the industry.

In this blog post, we will explore the techniques used in the art of lathe machining for developing complex parts. We will also discuss how this technique can be applied to the invention or product design process to create innovative and functional products. So, let’s dive in and discover the world of lathe machining!

THE ART OF LATHE MACHINING: TECHNIQUES FOR DEVELOPING COMPLEX PARTS

Lathe machining is a process that has been around for centuries. It is a technique that involves the use of a lathe machine to shape and cut materials into complex parts. The art of lathe machining is a skill that requires precision, patience, and attention to detail. In this article, we will explore the techniques used in lathe machining to develop complex parts.

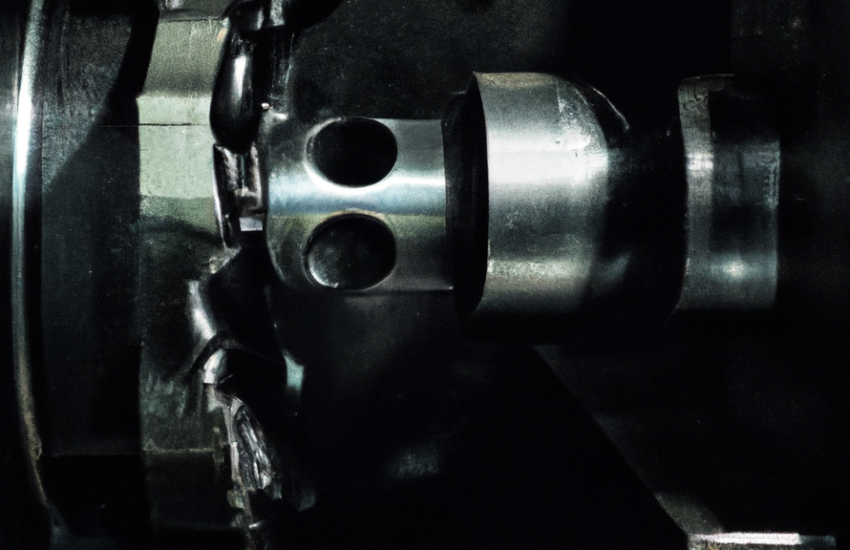

Lathe machining is a process that involves the use of a lathe machine to shape and cut materials into complex parts.

The lathe machine is a tool that rotates the material being worked on while a cutting tool is used to shape and cut the material. The cutting tool is held in place by a tool post and is moved along the material being worked on to create the desired shape.

- One of the most important techniques used in lathe machining is the use of different cutting tools. There are many different types of cutting tools that can be used in lathe machining, each with its own unique properties.

- Some cutting tools are designed for roughing out material, while others are designed for finishing work. The choice of cutting tool will depend on the material being worked on and the desired outcome.

Another important technique used in lathe machining is the use of different speeds and feeds. The speed of the lathe machine can be adjusted to control the rate at which the material is rotated. The feed rate can also be adjusted to control the rate at which the cutting tool moves along the material being worked on.

The speed and feed rate will depend on the material being worked on and the desired outcome.

One of the most challenging aspects of lathe machining is developing complex parts. Complex parts require a high degree of precision and attention to detail. There are several techniques that can be used to develop complex parts in lathe machining.

- One technique that is commonly used in lathe machining is the use of jigs and fixtures. Jigs and fixtures are devices that are used to hold the material being worked on in place.

- They can be used to ensure that the material is held in the correct position and orientation, which is essential for developing complex parts.

- Another technique that is commonly used in lathe machining is the use of multiple cutting tools. Multiple cutting tools can be used to create complex shapes and contours. The cutting tools can be used in combination with each other to create intricate designs and patterns.

In addition to these techniques, there are several other factors that can affect the outcome of lathe machining. One of the most important factors is the choice of material.

Different materials have different properties and require different cutting tools and techniques. The choice of material will depend on the desired outcome and the properties of the material being worked on.

Another important factor is the skill and experience of the lathe machinist. Lathe machining is a skill that requires years of practice and experience. A skilled lathe machinist will be able to develop complex parts with a high degree of precision and accuracy.

In conclusion, lathe machining is a process that requires precision, patience, and attention to detail.

The art of lathe machining involves the use of different cutting tools, speeds, and feeds to shape and cut materials into complex parts. Developing complex parts requires the use of jigs and fixtures, multiple cutting tools, and a high degree of skill and experience. The choice of material and the desired outcome will also affect the outcome of lathe machining. With the right techniques and skills, lathe machining can be used to develop complex parts that are both functional and aesthetically pleasing.

- Three-dimensional printing versus conventional machining in the …

Jul 1, 2020 … The dilator was also machined in stainless steel using a lathe. … parts, manufacturing complex parts which conventional methods cannot … - Sr Machinist – Job Descriptions – Human Resources :: The University …

Jun 13, 2020 … This position produces complex R&D prototype machined parts and components by programming, setting up, and operating computer numerical … - Metalworking – Wikipedia

Metalworking is the process of shaping and reshaping metals to create useful objects, parts, assemblies, and large scale structures. As a term it covers a … - CNC Precision Machining Services | Astro Machine Works

Utilizing the most up-to-date CNC milling machines our CNC turning and milling service is an excellent solution for creating parts featuring complex shapes and … - How CNC parts are improving the manufacturing industry …

Jan 17, 2019 … CNC Machining is a manufacturing process in which a set of … manual lathes; a CNC lathe can also be used for creating complex geometries. - What is Swiss Machining? Here is What You Need to Know

Jun 27, 2022 … Swiss machining is a superb manufacturing method that turns a bar stock … CNC Swiss lathe machines can fabricate extremely complex parts … - Trace-A-Matic: World-Class Precision Machining Quality Parts

Your source for precision machining of complex and intricate metal components that meets or exceeds the most critical tolerances. - CNC Machining Archives – EMC Precision

Apr 5, 2022 … Of all the machining processes available, CNC machining is one of the … machining for incredibly intricate and precise machining parts … - Additive vs. Subtractive Manufacturing | Formlabs

Additive technologies are also typically better suited for small parts and highly complex or intricate designs. When later stages of the development process … - CNC Application Engineering Services | Methods Machine Tools

That’s why our application engineers partner with you to select the right machines and tools, develop strategic processes, and deliver part workholding and …

Stuff about The Art of Lathe Machining: Techniques for Developing Complex Parts you didn’t know

- The lathe machine was invented in ancient Egypt around 1300 BC.

- Leonardo da Vinci designed a lathe machine that could cut screws in the late 15th century.

- The Industrial Revolution led to the development of more advanced and efficient lathes, which helped spur manufacturing growth.

- CNC (Computer Numerical Control) machines have revolutionized modern machining by allowing for precise and complex designs to be created with ease.

- Lathe machining is used in a variety of industries, including aerospace, automotive, medical device manufacturing, and more.

- Machinists who specialize in lathe work are highly skilled professionals who must undergo extensive training and apprenticeships before becoming proficient at their craft.

- In addition to lathes themselves, there are many different types of cutting tools that can be used on them depending on the desired outcome or material being worked with (e.g., carbide inserts for harder materials).

- Some common products made using lathe machining include gears, shafts, bolts/screws/nuts/washers/fasteners/valves/pins/bushings/fittings/couplings/connectors/housings/flanges/brackets/clamps/etc., as well as decorative items like candlesticks or chess pieces!

Are you ready to become an inventor?

Getting your idea out of your head and into your hands is only the first in a long set of steps towards becoming a successful inventor.

First Steps To A Successful Invention

At Invention Therapy, we believe that the power of the internet makes it easier than you think to turn your invention idea into a reality. In most cases, you can build a prototype and start manufacturing a product on your own. Changing your way of thinking can be difficult. Being an inventor requires you to balance your passion with the reality of having to sell your products for a profit. After all, if we can't make a profit, we won't be able to keep the lights on and continue to invent more amazing things!Please subscribe to our Youtube Channel!